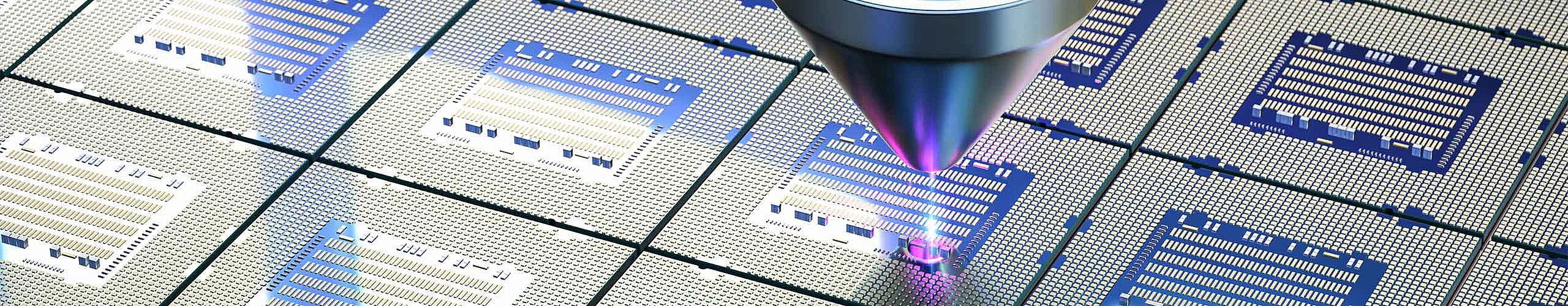

The processes of assembling components from semiconductor manufacturing or micro- and nanotechnology (MEMS) into a microelectronic component increasingly follow those of the semiconductor industry in their requirements.

These manufacturing steps concern, for example, the production of a MEMS (Micro-Electro-Mechanical System), a MOMS (Micro-Opto-Electro-Mechanical System) and the separation and electrical connection of the components to form a functional system.

SiP (System-in-Package) components combine various semiconductor structures of the latest design to form an electronic component of high power density. The SiP components must be joined together perfectly and contamination-free at the contact points. The production of high-density (HD) conductive tracks for connecting microelectronic components also requires constantly improved processes due to the integration density requirements, which are becoming increasingly similar to those of semiconductor production.

In all of the above cases, ultra-fine structures must be produced using complex exposure processes. Airborne trace components can impair imaging and patterning production equipment in terms of throughput and image quality.

Corrosive airborne components can lead to delayed damage of MEMS, SiP and HD tracks.

The analytical methods and systems of artemis control are used to identify the sources of contamination, to initiate remedial measures and to preventively eliminate the influence of contamination on the device and product.

The statements on the causes of possible malfunctions, the type and effectiveness of the remedial action, the required products and their duration of use are developed and reported site-specifically and in relation to the customer process.